False Solutions

False Solution 1:

Bioplastics

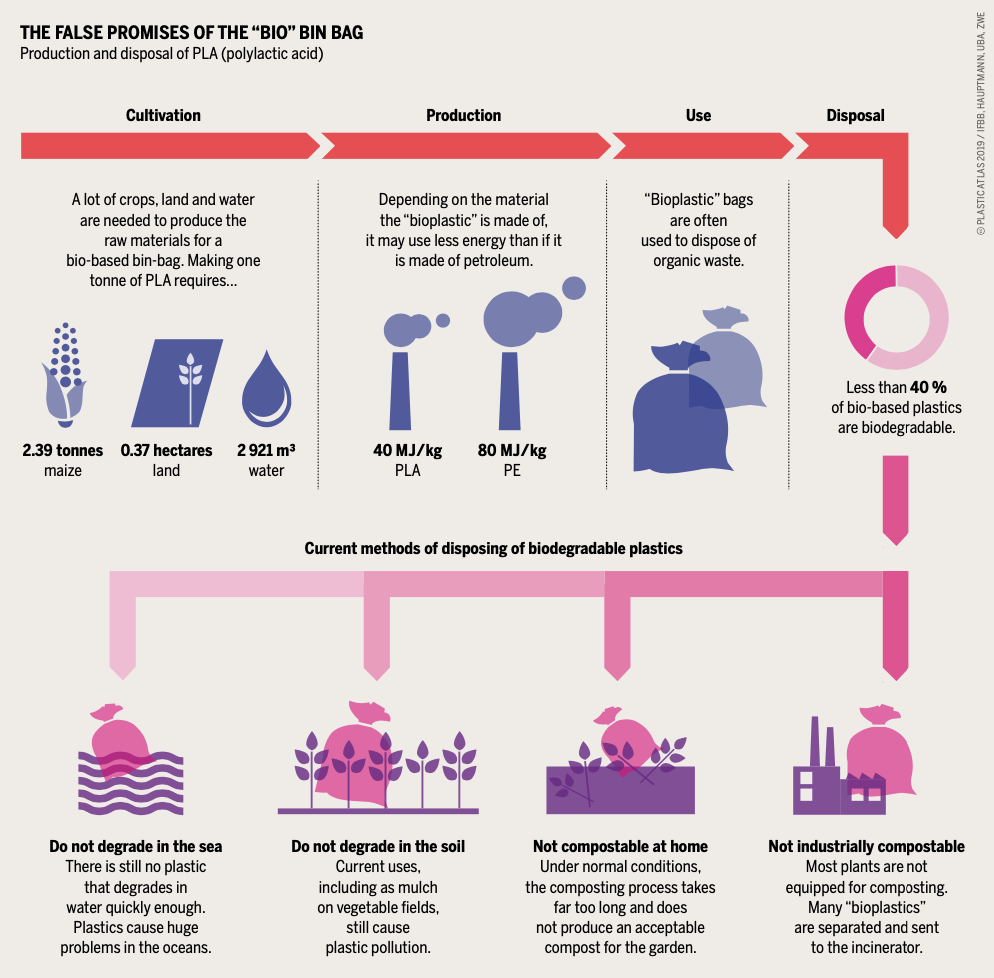

Bioplastics come with the implicit assurance that these products will biodegrade more quickly than regular plastic products, however, bioplastics only shift the problem of single-use plastic consumption and draws attention away from the real solutions.

They come in two main types: bio-based and biodegradable:

Bio-based

Bio-based plastics are based on raw materials such as sugarcane, potatoes, and maize, which are grown as monocultures in large-scale industrial farms and use considerable amounts of pesticides, some of which are banned in the European Union.Only a small portion of the plastic may be renewable . To be called a bioplastic, a material only needs 20 percent of renewable material; the other 80 percent could be fossil fuel-based plastic resins and synthetic additives.

Although replacing fossil materials with agricultural commodities seem unproblematic, this industry is projected to grow in the coming years, which means that the pressure on available agreeable land will rise - adding on to the already existing water shortages, species extinction, desertification, deforestation, and the lost of natural habitat from intensive industrialized agriculture

Biodegradable

Biodegradable products are designed to be degraded by the natural environment through the action of naturally occurring microorganisms under specific conditions (Heinrich Böll Foundation et al, 2019), although there are no promises about not leaving toxic residues behind.There is an assumption that a biodegradable product will biodegrade within a single season, but the process depends on where the item ends up and the temperature of the location.

More Resources:

- The Problem with Bioplastics

- What you need to know about plant-based plastics

- Why biodegradables won’t solve the plastic crisis

False Solution 2:

Waste-To-Energy Incinerators

When dumping waste in a landfill becomes impractical or politically unpopular, societies have typically burned that waste in machines called incinerators, most of which are usually located in communities that are culturally, racially, economically, and politically marginalized.

Waste-to-Energy facilities are among the most aggressively promoted incinerators, which claim to ‘disappear’ waste and generate energy during the process.

More Resources:

Books, Articles, and Reports:

- Arkin, Claire. (2019). No Time to Waste: GAIA, the Goldman Environmental Prize, and a Movement to Eliminate Waste Incinerators

- GAIA: Resources for Incinerators and Cement Kilns

- Gwash, Emily and Schroeder, Austin. (2014). Politics Starts Locally: The Legacy Of The 'Mothers of East L.A.'

- Pardo, Mary. (1990). Mexican American Women Grassroots Community Activists: "Mothers of East Los Angeles"

- Tishman Environment and Design Center. (2019). U.S. Municipal Solid Waste Incinerators: An Industry in Decline

- Tishman Environment and Design Center. (2019). 4.4 million people in the U.S. are exposed to pollution from waste incinerators.

- Tishman Environment and Design Center. (2019). Here's Why Communities on the East Coast Are Resisting Incineration

False Solution 5:

Chemical Recycling

This section was curated in collaboration with Doan Moon from GAIA.

Industry is now pushing for a new technological fix for plastic waste, called “chemical recycling.” New proposals are popping up in Australia, the EU, Indonesia, Malaysia,Thailand, and the U.S., increasingly supported by favorable legislation.

Research shows that chemical recycling is polluting, energy intensive, and has a track record of technical failures. In a society that urgently needs to transition from an extractive, fossil fuel economy to a circular one, chemical recycling is a distraction at best. Far more mature and viable solutions are to be found in upstream, zero waste strategies which focus on reducing the production and consumption of plastic.

Evidence illustrates that “chemical recycling” is not a viable solution for the plastic problem.

Below are technical, economic, and environmental problems abound:

- “Chemical recycling” releases toxic chemicals into the environment. Plastic contains a wide range of toxicants, and treating plastic with high temperature creates even more. The toxicants remain in both the products and byproducts, and end up released into the environment as air emissions and toxic residues, especially if outputs are burned.

- CR/PTF facilities place a heavy toxic burden on communities and workers, impacting people at plastic waste processing sites, in the end use of the products they produce, and at the facilities where the waste created by the process is dumped, destroyed, or treated.

- For economic and regulatory reasons, chemical recycling operations are mostly likely to be co-located with existing petrochemical facilities. This will further increase the environmental health impacts on communities that are already subject to disproportionate, cumulative environmental burdens.

- “Chemical recycling” has a large carbon footprint. The processes are energy intensive and rely on external energy. In addition to the direct GHG emissions from the process and burning the outputs, chemical recycling further aggravates climate change by perpetuating continued extraction of fossil fuel for plastic production.

- In addition to CO2 emissions associated with the external energy inputs, the chemical conversion process generates significant quantities of CO2. This is particularly the case for gasification, which loses more than half of the carbon in the plastic feedstock during the output upgrading phase. -- Over 53% of feedstock carbon would be lost in oil upgrading and 48% in gas upgrading.

- “Chemical recycling” has not yet been proven to work at scale. Chemical recycling is not equipped for commercial scale-up, nor is it able to take a leading role in tackling the rapidly growing global plastic waste problem. Commercial operations are rare, and the plants face technological hurdles in each phase of the process, from feedstock processing to cleaning and upgrading the resulting gas and oil. Solvent-based technologies are even less mature compared to pyrolysis and gasification.

- Of the 37 plastic “chemical recycling'' facilities proposed since the early 2000’s, based on publicly available information, only 3 are currently operational and none are successfully recovering plastic to produce new plastic (as of July 2020).

- Even in the industrial sector, some have estimated that it is optimistic to consider that chemical recycling of waste plastics will be viable within the next decade.

- “Chemical recycling” cannot compete in the market. The industry has a track record of major failures, and both plastic-to-plastic repolymerization and plastic-to-fuel require costly energy inputs. The final outputs are unable to compete with virgin polymers

- “Chemical recycling” does not fit in a circular economy. Most operations burn the outputs as fuel, and even with the most advanced technology, very little of the waste plastic actually becomes new plastic. As such, chemical recycling does not have a place in a circular economy, unless it displaces virgin plastic production. In a society that urgently needs to transition from an extractive, fossil fuel economy to a circular one, chemical recycling is a distraction at best. Far more mature and viable solutions are to be found in upstream, zero waste strategies which focus on reducing the production and consumption of plastic.

Cities and states must focus on what actually works: reducing the amount of plastic produced and transitioning to zero waste systems.

Resources

-

Patel, D., Moon, D., Tangri, N. & Wilson, M. (2020). All Talk and No Recycling: An Investigation of the U.S. “Chemical Recycling” Industry. Global Alliance for Incinerator Alternatives. doi:10.46556/WMSM7198. Retrieved from: https://www.no-burn.org/chemical-recycling-us

-

PlastEurope. (2018, July). Closure of operation in Italy / Phthalates issue under REACH brings down European PVC recycling project. Available at: https://www.plasteurope.com/news/VINYLOOP_t240095

-

Rollinson, A. & Oladejo, J. (2020). Chemical Recycling: Status, Sustainability, and Environmental Impacts. Global Alliance for Incinerator Alternatives. doi:10.46556/ONLS4535. Retrieved from: https://www.no-burn.org/cr-technical-assessment

-

Tabrizi S, Rollinson A, Hoffmann M & Favoino E. (2020). Understanding the Environmental Impacts of Chemical Recycling - ten concerns with existing life cycle assessments. Zero Waste Europe. Available at: https://zerowasteeurope.eu/library/understanding-the-environmental-impacts-of-chemical-recycling-ten-concerns-with-existing-life-cycle-assessments